Single Row Tapered Roller Bearings

- Radial and axial load capacity

- High rigidity

- Easy to install and adjust

- Good wear resistance

- Wide application range

- Economical and low cost

- Can be used in pairs

In short, single-row tapered roller bearings have become a common bearing type in many industrial equipment due to their simple structure, easy installation, economical and practical characteristics.

Introduction

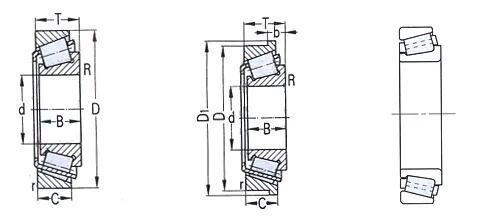

Single Row Tapered Roller Bearings are a category of rolling-element bearings equipped with tapered rollers, engineered to manage both radial and axial forces at the same time. These bearings are composed of an inner ring, an outer ring, tapered rollers, and a cage to maintain roller spacing. The tapered geometry of the rollers creates linear contact with the raceways, allowing for efficient load distribution and minimized friction. This configuration makes single row tapered roller bearings well-suited for applications requiring the support of moderate radial and axial loads.

Main Model Parameters Table

Below are some common models of single row tapered roller bearings along with their key parameters:

Applications

Single row tapered roller bearings are extensively utilized across multiple industries because of their capacity to manage both radial and axial forces. Key applications include:

- Automotive Sector: Employed in wheel hubs, drive shafts, and differential systems for cars and trucks.

- Construction Equipment: Frequently used in machinery such as excavators, bulldozers, cranes, and other heavy-duty equipment.

- Industrial Equipment: Integrated into gearboxes, motors, and bearing housings within manufacturing facilities.

- Rail Transport: Utilized in wheel bearings for trains and other rail vehicles.

- Mining Operations: Found in heavy-duty machinery like crushers and conveyors.

- Aerospace Industry: Applied in specialized lightweight and high-precision systems.

Features

- Exceptional Load Handling: Single row tapered roller bearings are capable of supporting significant radial and unidirectional axial loads, making them ideal for scenarios involving combined loading.

- Space-Efficient Design: The tapered roller configuration allows for a compact and efficient structure, perfect for installations with limited space.

- Precision Performance: The accurate contact between the rollers and raceways ensures smooth functioning with low levels of vibration and noise.

- Self-Adjusting Capability: These bearings offer a degree of self-alignment, minimizing the impact of installation inaccuracies or angular deviations on performance.

- Durability in Harsh Conditions: Designed to withstand high loads, speeds, and temperatures, single row tapered roller bearings deliver extended service life and dependable operation in demanding environments.

Summary

Single row tapered roller bearings are a critical element in numerous industries, offering effective load management and consistent performance. They are engineered to support both radial and axial forces, making them perfect for applications involving combined loads. Their space-saving design, robust load-bearing capacity, and self-aligning features make them versatile for use in sectors such as automotive, construction equipment, industrial machinery, railways, and mining.

Owing to their capability to function under high loads and speeds while ensuring smooth operation, single row tapered roller bearings have become indispensable in modern mechanical systems. Ongoing innovations in design and production techniques ensure these bearings continue to meet the growing demands of industries that prioritize precision and dependability.