In the field of shipbuilding and marine engineering, the application of bearings is crucial because the particularity of the marine environment places extremely high demands on mechanical systems. Offshore equipment needs to have corrosion resistance, high reliability, and the ability to operate stably and for a long time under harsh conditions. As a core component, bearings play an irreplaceable role in ship power systems, propulsion systems, and various equipment on offshore platforms. The following are the main application scenarios of bearings in this field:

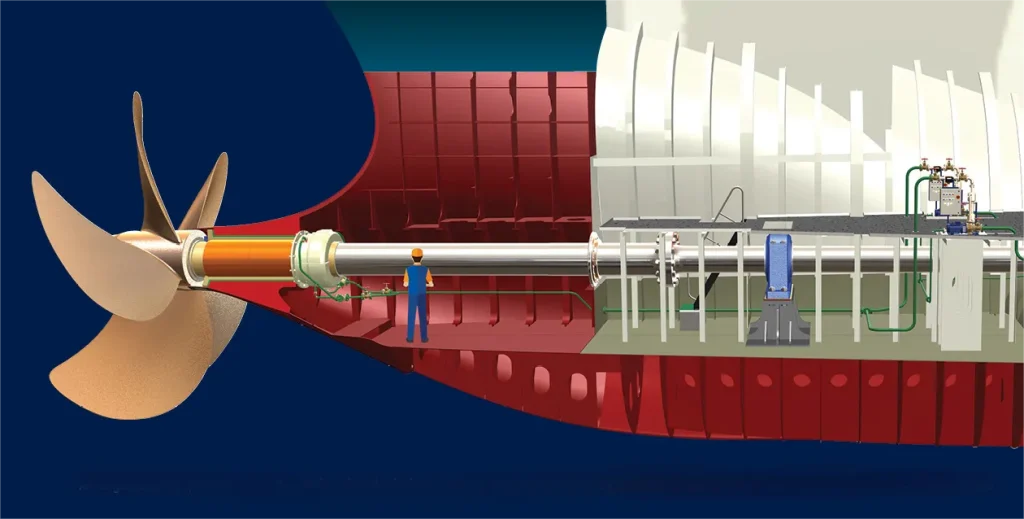

Ship propulsion system

Bearings play a key role in ship propulsion systems, especially in the main engine and propulsion shaft system. They support and guide the rotation of the propulsion shaft and bear the huge axial and radial loads from the propeller. Due to the corrosive and high-load conditions of the seawater environment, bearings must have extremely strong corrosion resistance and high load-bearing capacity.

- Propeller bearings: used to connect the propeller to the engine, withstand high pressure and speed, common types include radial ball bearings, cylindrical roller bearings, etc.

- Floating bearings: used in ships such as tankers and cargo ships to reduce vibration caused by axial loads.

Steering gear system

The steering gear is the core of ship direction control. The bearings in the steering gear system ensure the smooth rotation of the rudder bar and reduce friction and wear. Since the steering gear needs to withstand the influence of waves and wind, the bearings must ensure long-term stable operation to ensure safe navigation.

Ship main engine and auxiliary power system

Ship main engine (such as diesel engine) and auxiliary power system (such as generator set) rely on bearings to support the movement of rotor and crankshaft. These bearings need to maintain good lubrication and operating performance under high temperature and high load conditions.

- Crankshaft bearings: withstand the high pressure of the engine crankshaft and need to have high temperature resistance and wear resistance.

- Motor bearings: used for motors in auxiliary systems to support high load operation.

Offshore platform equipment

Offshore platforms (such as oil drilling platforms and offshore wind farms) operate in extreme environments, and the corrosion resistance, high pressure resistance and wear resistance of bearings are crucial.

- Drilling equipment: Rotating equipment (such as turntables, drive shafts) rely on high-quality bearings to ensure precise movement.

- Offshore wind turbines: Bearings are used in transmission systems and generators and need to have corrosion resistance and vibration resistance.

Marine towing equipment

Bearings in tugboats, cables and lifting equipment are used to support the rotating parts of towing devices and winches. These devices need to withstand the impact of waves, tides and strong winds, and bearings ensure their smooth operation and long-term reliability.

Floating platforms and floating structures of ships

Floating platforms (such as oil and gas platforms, floating ports) rely on bearings to support rotating parts (such as lifting equipment and slewing platforms) to ensure the stability of the structure and the normal operation of the equipment.

Anti-corrosion protection and lubrication system

Due to the strong corrosiveness of seawater, bearing materials and coating technology are crucial. Stainless steel, ceramics or special alloy materials are often used to manufacture corrosion-resistant bearings, and are combined with efficient lubrication systems to reduce wear and extend service life.

Subsea machinery and equipment

Subsea machinery such as deep-sea detectors and subsea mining equipment rely on bearings to support moving parts. These bearings need to have high pressure resistance, wear resistance, and can effectively prevent seawater intrusion and corrosion.

Резюме

Bearings are widely used in ships and marine engineering, covering multiple fields such as propulsion systems, power equipment, offshore platforms and subsea equipment. In order to cope with the harsh conditions of the marine environment, bearings need to have the characteristics of corrosion resistance, high pressure resistance, and high load resistance, and use special materials and lubrication technology to ensure long-term reliable operation. These high-performance bearings provide important guarantees for the safety and efficiency of ships and offshore engineering equipment.