リニアローラーベアリング

Linear roller bearings are a type of bearing designed for linear motion. They use rollers as rolling elements and have the following characteristics and performance:

Features:

High load capacity

Low friction, high efficiency

High precision, high rigidity, etc.

Strong durability

Multiple lubrication methods

Multiple installation methods

Performance:

High rigidity

Low friction

High precision

Long life

Linear roller bearings are widely used in machine tools, automation equipment, semiconductor manufacturing, medical instruments and other fields, and are an indispensable key component in modern industry.

1. Product Introduction of Linear Roller Bearing

Linear roller bearing is a type of bearing designed for linear motion. They use rollers as rolling elements and can achieve low-friction, high-precision linear motion on guide rails. Compared with linear ball bearings, linear roller bearings have higher load-bearing capacity and rigidity and are widely used in machine tools, automation equipment, precision measurement systems, and semiconductor manufacturing.

2. Main models of Linear Roller Bearing

Linear roller bearings can be divided into the following categories according to design and application requirements:

Model Category Common Series Features

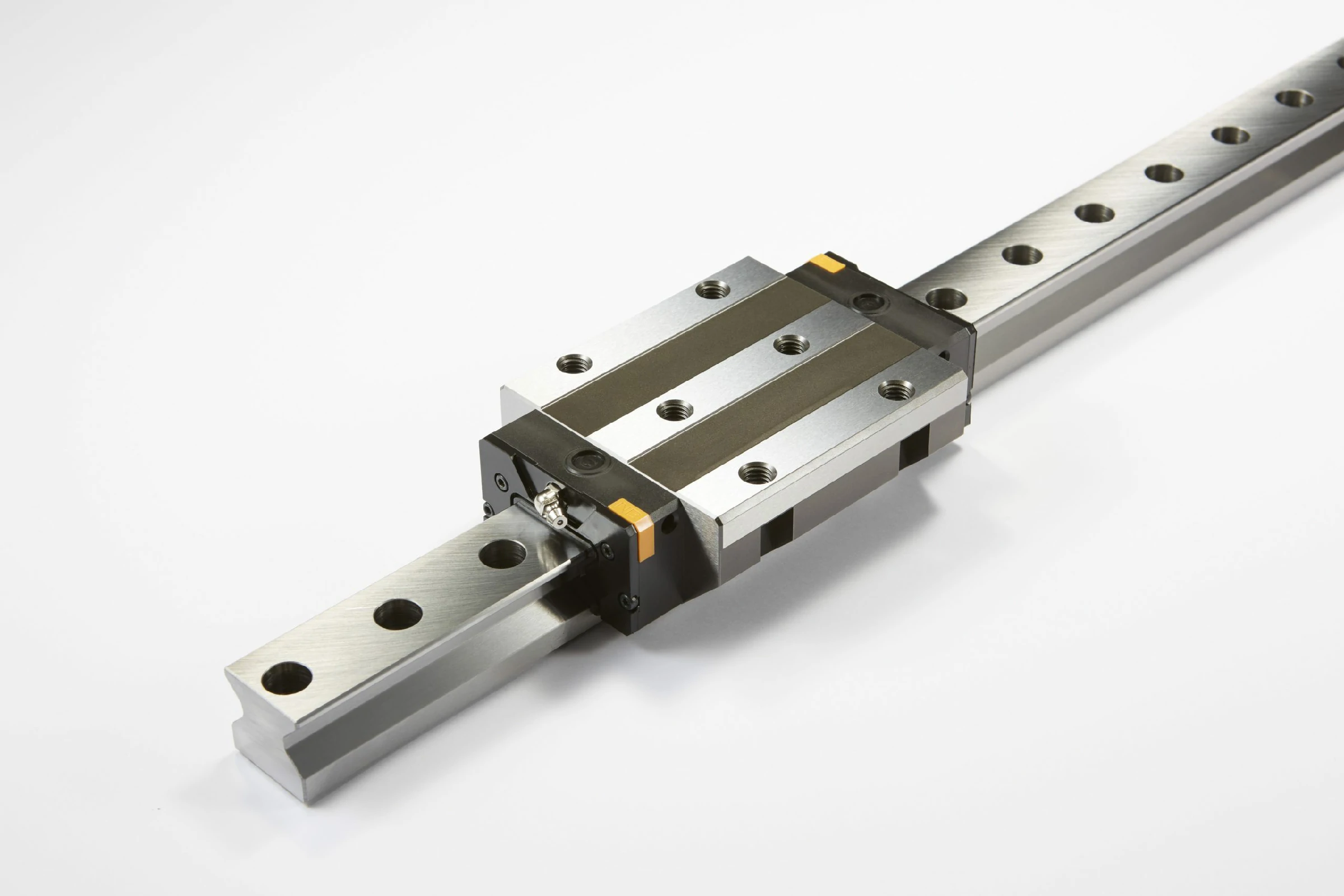

Standard type LFR, LR, LRB are suitable for standard guide rails, running smoothly and easy to install

High-load type LWRB, LWRM are suitable for heavy-duty linear guide rail systems with strong load-bearing capacity

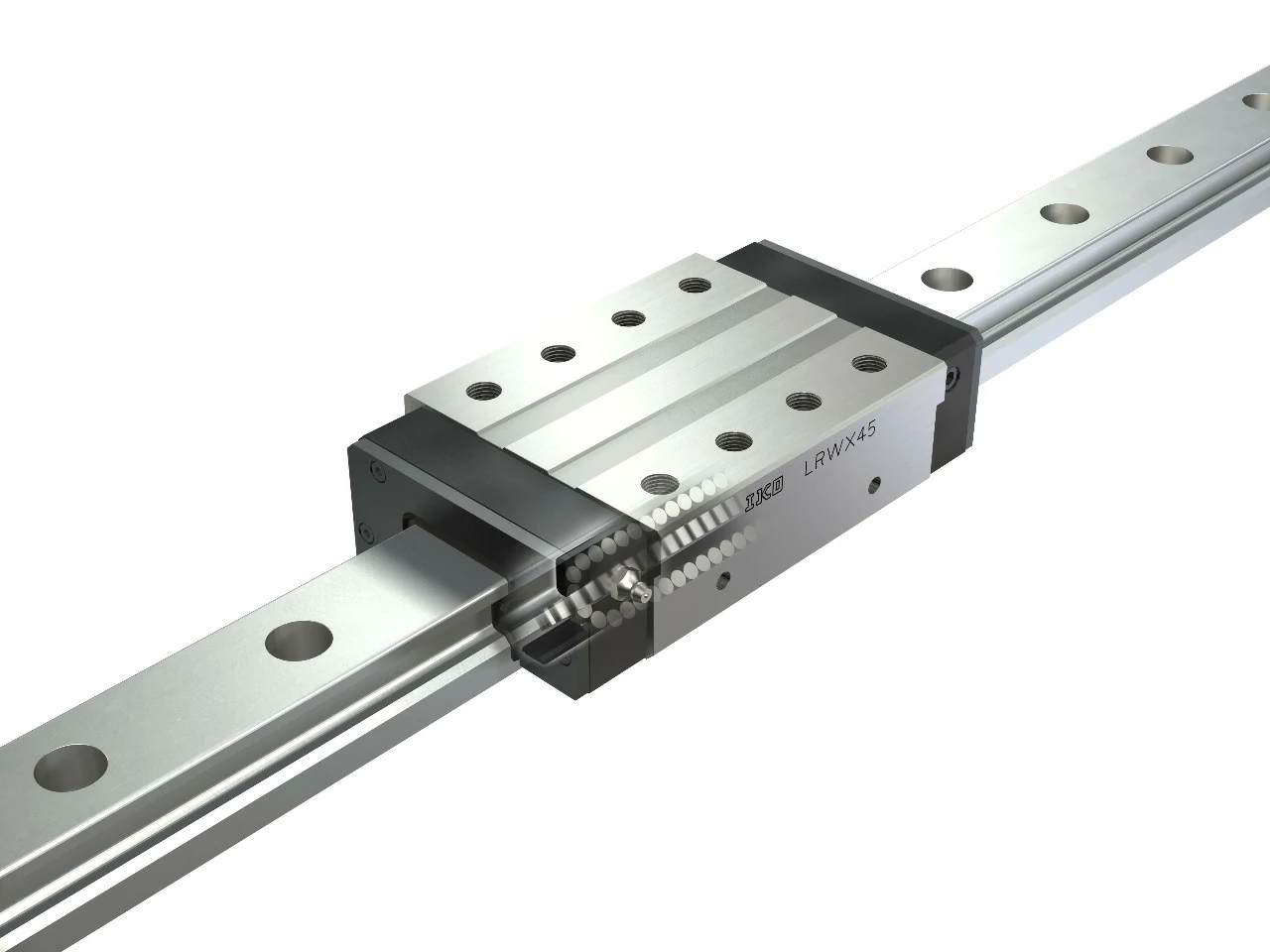

Precision type LRX, LRG are suitable for high-precision occasions, such as semiconductor manufacturing

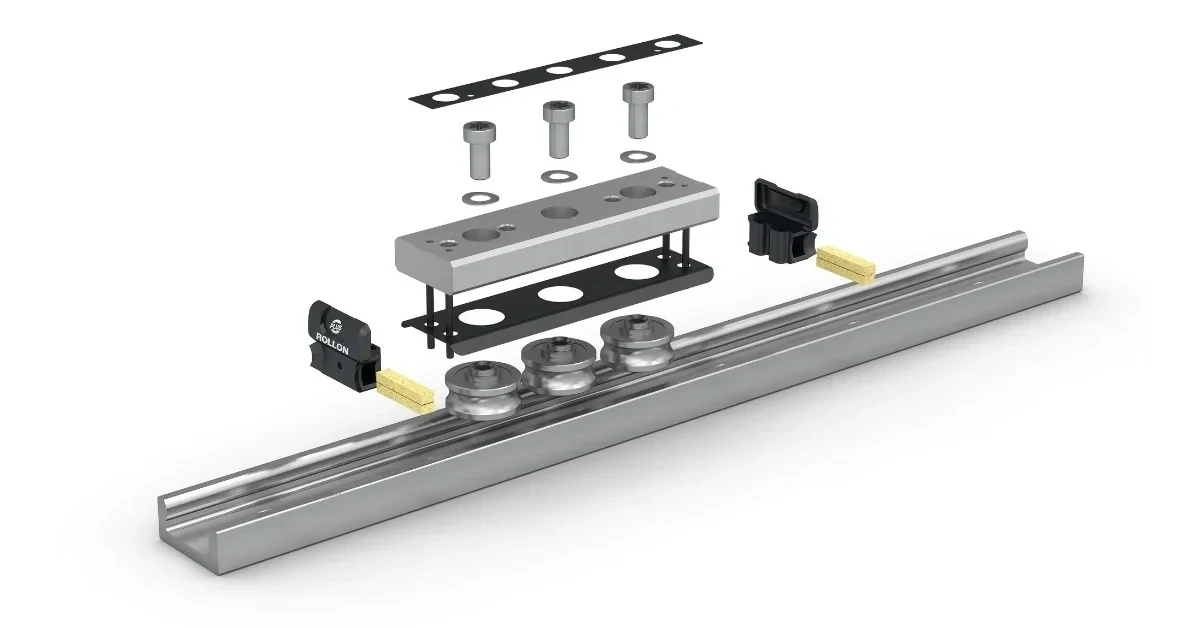

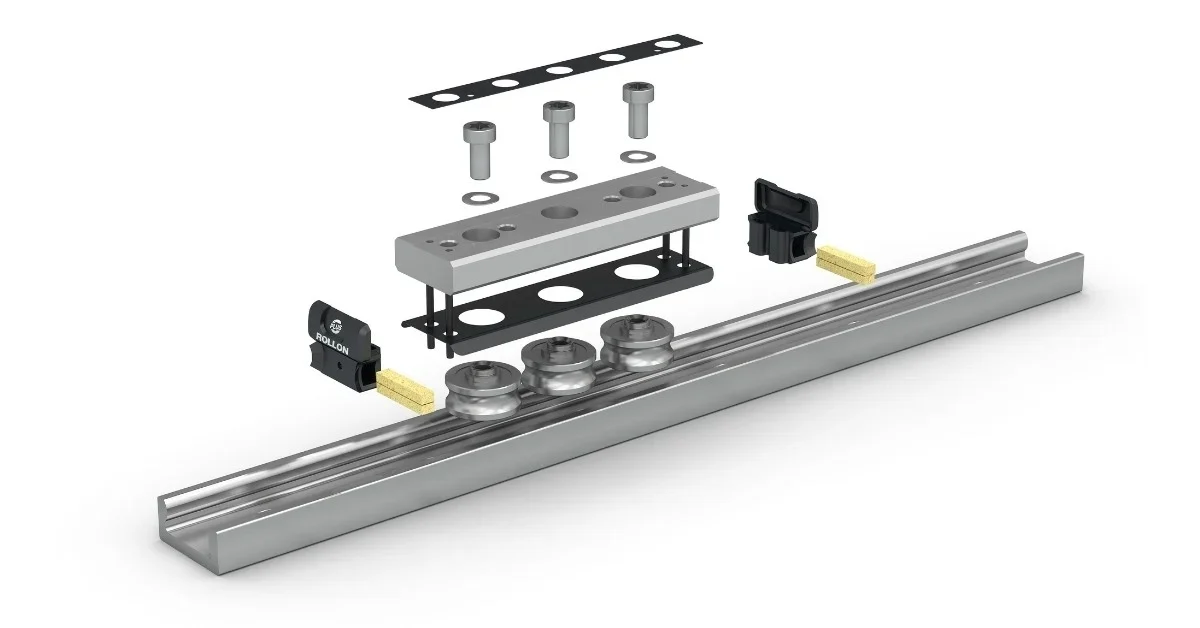

Composite type Caged Roller adopts roller cage design to reduce friction and increase speed

3. Application fields

Linear roller bearings are widely used in many industries due to their high rigidity, low friction and high precision:

(1) Industrial automation

Guide rail systems used in automated production lines to ensure smooth and high-speed operation of equipment

Applied to the sliding parts of CNC machine tools to improve processing accuracy and efficiency.

(2) Machine tool equipment

Applicable to CNC machine tools, milling machines, grinders and other equipment to provide high-precision linear motion.

Used in gantry machining centers to withstand high loads and maintain smooth operation.

(3) Semiconductor and optical equipment

Applicable to chip manufacturing equipment to ensure ultra-precision motion control.

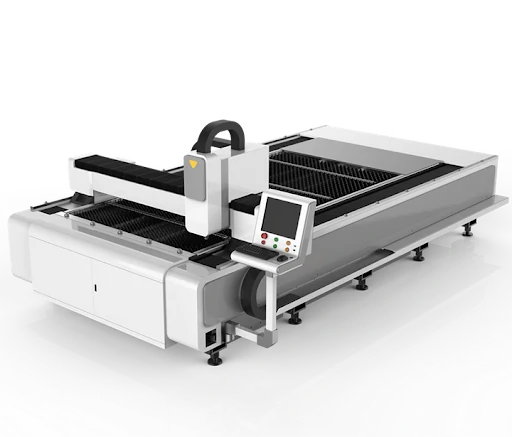

Applied to laser cutting machines and 3D printers to ensure high stability and precise positioning.

(4) Medical equipment

Applicable to the sliding system of precision instruments such as CT scanners and X-ray equipment.

Used in surgical robots to improve accuracy and stability.

(5) Logistics and transportation systems

Applicable to guide rails and sliders in automated warehousing systems.

Applicable to high-speed sorting equipment to improve operating efficiency.

4. Product features

High load capacity: Compared with linear ball bearings, roller bearings can withstand higher radial and axial loads.

Low friction and high efficiency: The roller has low rolling friction, achieving smooth linear motion and improving system efficiency.

High precision and high rigidity: suitable for machine tools, semiconductors and other occasions that require extremely high precision.

Strong durability: optimize materials and surface treatment technology to improve wear resistance and service life.

Multiple lubrication methods: support oil lubrication or grease lubrication to adapt to different working environments.

Multiple installation methods: provide flange type, embedded type, slider type and other installation methods to meet diverse needs.

5. FAQ

Q1: What is the difference between linear roller bearings and linear ball bearings?

Different rolling elements: Linear roller bearings use rollers, which have a larger contact area, stronger load capacity, and higher rigidity, and are suitable for high load and high precision occasions.

Q2: How to choose a suitable linear roller bearing?

The following factors need to be considered:

Load requirements (radial/axial load)

Precision requirements (normal precision, high precision, ultra-precision grade)

Operating speed (low speed/high speed application)

Installation space (different models are suitable for different installation methods)

Working environment (such as whether dustproof or waterproof design is required)

Q3: How to maintain linear roller bearings?

Check the lubrication status regularly and select the appropriate lubricant or grease.

Ensure that the mounting surface is clean to prevent dust and impurities from entering the bearing.

Avoid long-term operation of the bearing under extreme load or high speed to extend the service life.

Q4: Can linear roller bearings be used in high temperature environments?

Some models support high temperature environments (such as special steel or ceramic materials), but the operating temperature of ordinary steel bearings is usually limited to below 80°C. For high temperature environments, it is recommended to choose high temperature resistant materials or special lubrication solutions.

Q5: Can linear roller bearings replace sliding guides?

Yes, especially in situations where low friction, high load capacity and high precision are required, linear roller bearings are an ideal alternative to sliding guides.

6. Summary

Linear roller bearings are a high-performance bearing suitable for linear motion systems. They have the characteristics of high rigidity, low friction and high precision. They are widely used in machine tools, automation equipment, semiconductor manufacturing and medical instruments.

Selection suggestions:

Choose the appropriate roller diameter and specifications according to the load requirements.

Choose ordinary, high precision or ultra-precision according to the accuracy requirements.

Choose the appropriate lubrication method and installation method according to the operating environment.

Maintenance recommendations:

Check the lubrication status regularly to maintain good working performance.

Prevent impurities from entering to avoid affecting the life of the bearing.

Avoid overloading or high-speed operation that may cause bearing damage.

Linear roller bearings play an important role in modern industrial production and are key components in precision machinery and automation systems.