トラックローラーベアリング

トラックローラーベアリング is a type of bearing designed for linear or curved track systems. They are mainly used to support and guide moving parts. They can withstand high radial loads and certain axial loads under certain circumstances. This type of bearing is widely used in industrial automation, machine tools, conveying equipment, lifting machinery, robots and other fields.

Main specifications and model classification

Key parameters

Inner diameter (d): the diameter of the inner ring of the bearing, in millimeters (mm).

Outer diameter (D): the diameter of the outer ring of the bearing.

Width (B): the overall width of the bearing.

Roller type: divided into cylindrical rollers, needle rollers and ball rollers.

Rated dynamic load (C): the maximum load that the bearing can withstand in the running state.

Rated static load (C0): the maximum load capacity of the bearing in the static state.

Limiting speed: the maximum speed that the bearing can reach under specific conditions.

Sealing type: divided into open type, sealed type and dust cover type.

Installation method: common types include flange type, slider type and embedded type.

Common types

Cylindrical roller track bearings

Representative models: NATR, NUTR, KR, RNA and other series.

Features: With high radial load capacity, suitable for linear guide systems.

Needle roller track bearings

Representative models: HK, BK, RNA and other series.

Features: Compact structure, suitable for working conditions with limited space.

Ball roller track bearings

Representative model: Crown Track Roller Bearings.

Features: Supports both radial and axial loads, suitable for complex motion environments.

Application areas

Industrial automation: Linear guide systems for automation equipment, supporting components such as robotic arms and sliders.

Machine tools: Suitable for linear motion systems of CNC machine tools, grinders and other equipment to improve accuracy and rigidity.

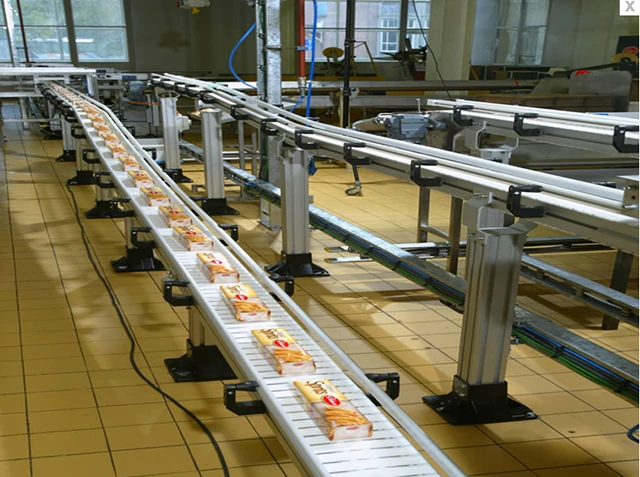

Conveying systems: In equipment such as conveyor belts and chain conveyors, stable operation is achieved and high loads can be tolerated.

Lifting equipment: Track systems for machinery such as cranes and hoists, providing strong support and withstanding high radial loads.

Robot: Ensure high precision and flexibility in robot joints and linear motion mechanisms.

Packaging equipment: Ensure high-speed operation and precise positioning of packaging machinery.

Summary

Railway roller bearings are important components of linear and curved motion systems, with high load capacity, high precision and long life. According to different working conditions, you can choose cylindrical rollers, needle rollers or ball rollers, and equip them with corresponding installation methods and sealing designs.

Core advantages

High radial load capacity, adapt to various load environments.

Support high-speed and high-precision movement to meet the needs of precision equipment.

Compact structure, suitable for occasions with limited space.

A variety of sealing methods to cope with different working environments.

Selection Guide

Select the type of roller according to the type of load (radial or axial).

Select the appropriate sealing design (open, sealed or dust cover) according to environmental conditions.

Select the appropriate installation method according to installation requirements.

Railway roller bearings are widely used in industrial automation, machine tools, lifting equipment and other industries, and are an important part of modern mechanical equipment.