Bearings are essential components in industrial machinery, found in nearly all equipment involving rotation, linear motion, or load support. They are critical for reducing friction, enhancing efficiency, prolonging equipment life, and ensuring stable mechanical performance. Below is an overview of their applications across various industrial machinery types, categorized by function and usage:

Motors and Generators

Functions:

Friction Reduction: Bearings support the rotor and stator, minimizing mechanical friction and ensuring smooth rotation, which boosts efficiency.

Efficiency Improvement: Without bearings, rotating parts would generate excessive friction and heat, reducing energy efficiency. Bearings help optimize performance.

Life Extension: By reducing wear on rotating components, bearings extend the lifespan of motors and generators.

Applications:

Rolling Bearings: Commonly used to support motor rotors, reducing friction.

Sliding Bearings: Often employed in large or high-power equipment for better support.

Pumps and Compressors

Functions:

Rotational Support: Bearings ensure smooth operation by supporting rotating shafts.

Load Handling: They withstand high pressures and flows in demanding industrial applications.

Sealing Enhancement: High-quality bearings with proper seals minimize oil or gas leakage.

Applications:

Rolling Bearings: Typically used for their ability to handle radial and axial loads.

Self-Lubricating Bearings: Ideal for harsh environments, reducing maintenance needs.

Transmission Systems (Gears, Chains, Belts)

Functions:

Power Transmission: Bearings enable smooth operation of gears, sprockets, and pulleys.

Wear Reduction: They minimize friction between moving parts, enhancing system efficiency.

Applications:

Rolling Bearings: Used in gearboxes, often deep groove ball or cylindrical roller types.

Needle Bearings: Suitable for compact designs with high space constraints.

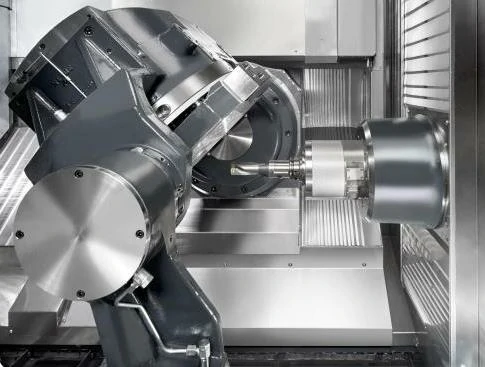

Machine Tools (Lathes, Milling Machines, Grinders)

Functions:

Precision Enhancement: Bearings support high-precision components, ensuring machining accuracy.

Load Handling: They withstand axial and radial forces from cutting operations.

Vibration Reduction: High-precision bearings minimize vibrations, improving machining quality.

Applications:

High-Precision Bearings: Angular contact ball bearings and cylindrical roller bearings are common.

Ultra-Precision Bearings: Used in advanced CNC machines for exceptional accuracy.

Conveying Equipment (Conveyor Belts, Chain Systems)

Functions:

Friction Reduction: Bearings ensure smooth operation of rollers and chains.

Load Support: They handle the weight of materials, especially in heavy-duty systems.

Durability: Bearings enhance the stability and lifespan of conveying systems.

Applications:

Roller Bearings: Support conveyor belt rollers for smooth rotation.

Needle Bearings: Used in high-load, space-constrained applications.

Summary:

Bearings are indispensable in industrial machinery, playing a key role in reducing friction, improving efficiency, extending equipment life, and ensuring precision. Their selection and maintenance are critical for the reliability and longevity of industrial equipment, with specific types chosen based on load, speed, and environmental conditions. Proper bearing use enhances performance and reduces operational costs.