Magnetic Levitation Linear Bearings

Core advantages of Magnetic Levitation Linear Bearing

✅ Zero friction: no wear, extremely long life

✅ Ultra-high precision: positioning accuracy up to ±0.1μm

✅ Ultra-high speed: speed up to 5~20m/s

✅ Maintenance-free: no lubrication required

✅ Clean and pollution-free: suitable for semiconductor and medical industries

Typical applications

Semiconductors: wafer handling, photolithography machines

Precision machine tools: nano-level processing equipment

Magnetic suspension transportation: high-speed logistics sorting lines

Optical systems: laser cutting, precision positioning

Medical equipment: MRI, surgical robots

Introduction to Magnetic Levitation Linear Bearing Technology

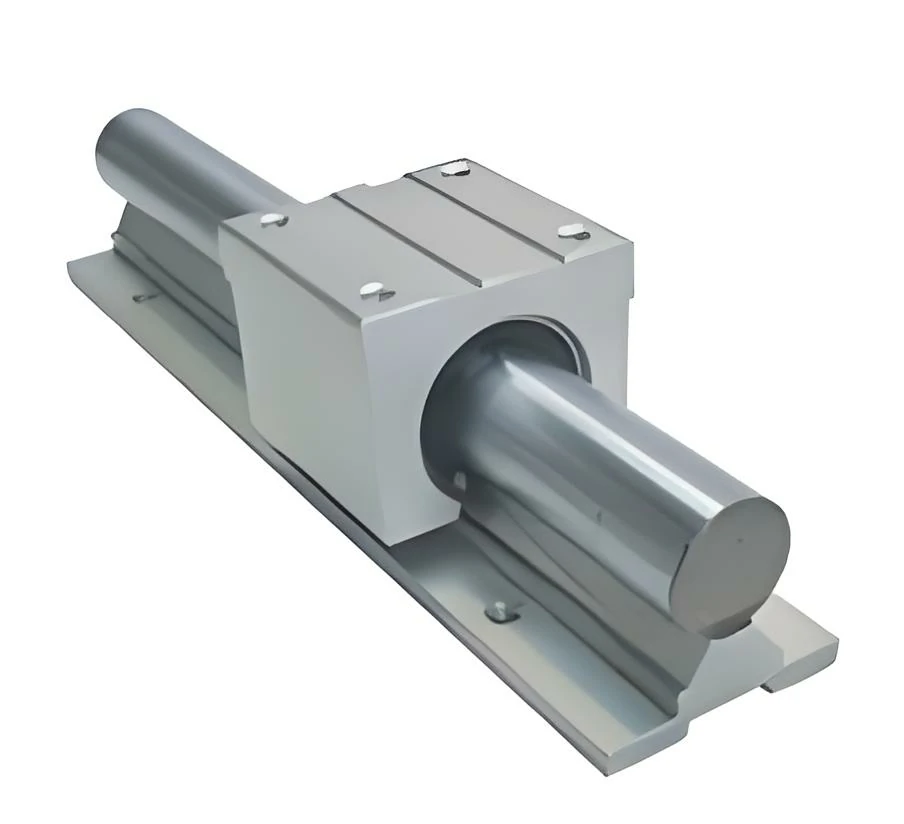

Magnetic Levitation Linear Bearing is a high-end bearing technology that achieves contactless suspension and linear motion based on electromagnetic force. It uses electromagnetic field control to maintain a micron-level air gap between the moving parts and the fixed track, completely eliminating mechanical friction, and is suitable for application scenarios requiring ultra-high speed, ultra-high precision and clean environment.

1. Core features and advantages

✅ Zero friction: no mechanical contact, no wear, extremely long life

✅ Ultra-high precision: positioning accuracy can reach ±0.1μm, repeatability accuracy ±0.01μm

✅ Ultra-high speed: speed can reach 5~20m/s (far exceeding ball screws and traditional guides)

✅ Maintenance-free: no lubrication required, reducing downtime

✅ Low vibration & silent: no mechanical collision, smooth operation

✅ Applicable to clean environments: no particle pollution, suitable for semiconductor, optical, and medical industries

2. Comparison of main product models and parameters

Model Brand Maximum load (N) Maximum speed (m/s) Accuracy (μm) Applicable temperature Typical application

MLX-200 Siemens 500 10 ±0.1 0~50°C Semiconductor wafer handling

LMG-150 Fanuc 300 15 ±0.05 5~40°C High-precision CNC machine tools

MagLev-300 Bosch 800 8 ±0.2 -10~60°C Maglev train drive

AirCore-100 Aerotech 200 20 ±0.01 10~30°C Optical precision positioning system

NSK MagRail NSK 1000 5 ±0.3 -20~70°C Industrial automation high-speed conveyor line

Note: Parameters of different manufacturers may vary due to control systems and cooling methods (such as air cooling/water cooling).

3. Product application analysis

(1) Semiconductor manufacturing

Application: wafer handling, photolithography machine workbench

Advantages: no vibration pollution, nanometer-level positioning, improved yield

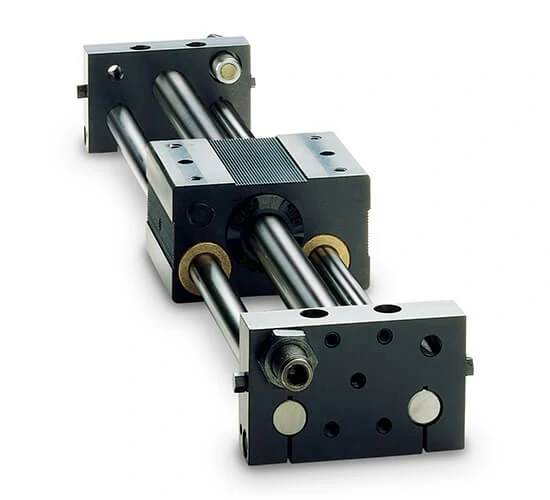

(2) Precision machine tools & measuring equipment

Application: ultra-precision lathe, three-coordinate measuring machine

Advantages: zero backlash, ultra-high repeatability

(3) Magnetic levitation transportation system

Application: maglev train (such as Shanghai Maglev), logistics sorting line

Advantages: high speed, low energy consumption, maintenance-free

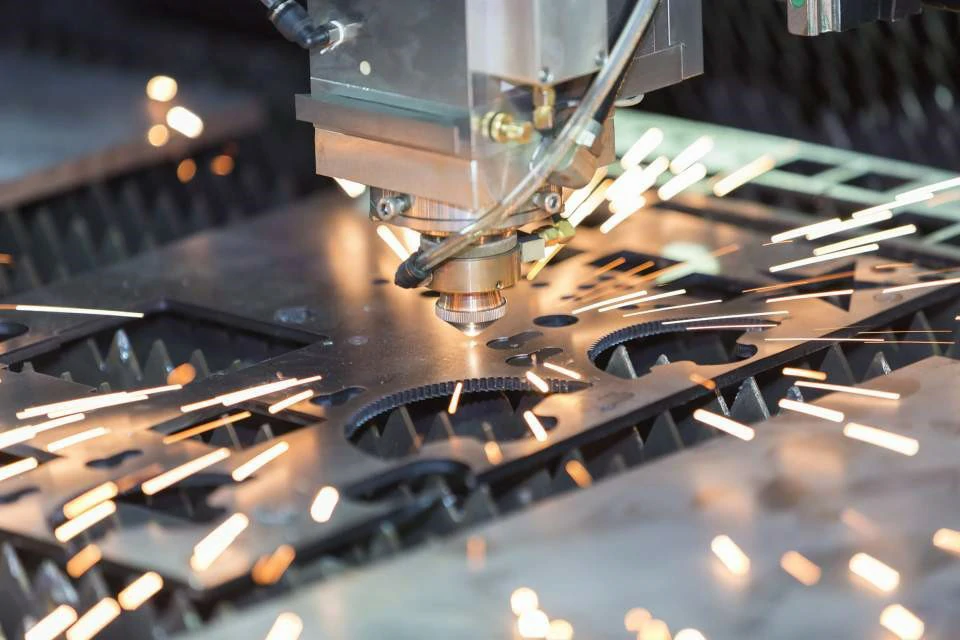

(4) Optical & laser processing

Application: laser cutting, optical calibration platform

Advantages: no friction jitter, ensure beam stability

(5) Medical equipment

Application: surgical robot, MRI equipment

Advantages: no metal interference, silent operation

4. Summary and FAQ

Q1: Does the magnetic levitation bearing require maintenance?

A: Basically maintenance-free, but the electromagnetic coil and sensor status need to be checked regularly.

Q2: Compared with traditional linear guides, what are the disadvantages of magnetic levitation bearings?

A: The cost is high (about 5 to 10 times), and a precision control system (such as PID adjustment) is required.

Q3: What is the life of Magnetic Levitation Linear Bearing?

A: The theoretical life is >100,000 hours (no mechanical wear), and the actual life depends on the aging of electronic components.

Q4: Is it suitable for high-load scenarios?

A: The current commercial model load is generally <1 ton, and overloads still require hydraulic or mechanical bearing assistance.

Q5: Future development trends?

A: Higher load (such as industrial robotic arms), lower power consumption (superconducting magnetic suspension), and smarter control (AI dynamic adjustment).

5. Conclusion

Magnetic Levitation Linear Bearing are a key technology in the high-end manufacturing industry, especially suitable for ultra-precision, ultra-high speed and clean environment requirements. Despite the high cost, its irreplaceable nature in the fields of semiconductors, optics, and medical care has led to continued market growth. In the future, with the development of superconducting materials and intelligent control technology, its application scope will be further expanded.