Plastic Sliding Linear Bearings

Overview of Plastic Linear plain Bearings

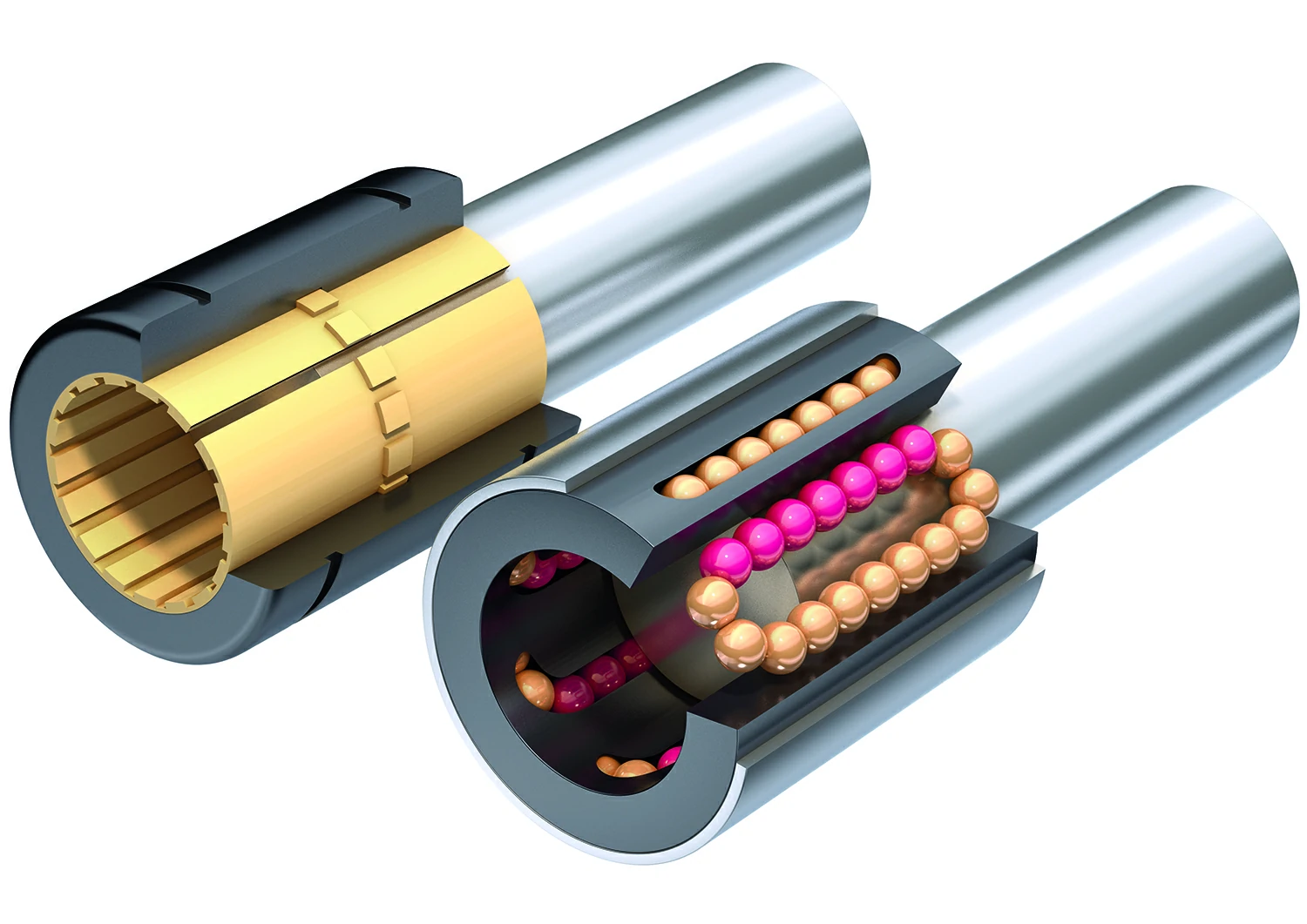

Plastic Sliding Linear bearings are linear motion components that use high-performance polymers as friction pairs and achieve low resistance and silent operation by virtue of the lubrication properties of the material itself. Compared with metal bearings, these bearings have better chemical corrosion resistance and do not require external lubricants, making them suitable for harsh working conditions. Common substrates include polytetrafluoroethylene (PTFE), polyethylene (PE), nylon (PA) and polyurethane (PU).

Technical parameters of typical models

The following table lists the performance indicators of several mainstream engineering plastic sliding bearings, covering common types such as self-lubricating nylon (PA) and polyethylene (PE):

Note: Actual performance may fluctuate due to material modification, process differences or changes in working conditions. It is recommended to verify specific parameters through experiments.

Common brands

SKF Plastic Sliding Linear bearings

NSK Plastic Sliding Linear bearings

FAG Plastic Sliding Linear bearings

NTN Plastic Sliding Linear bearings

TIMKEM Plastic Sliding Linear bearings

INA Plastic Sliding Linear bearings

JTEKT Plastic Sliding Linear bearings

Typical application areas

Industrial automation

Applicable to equipment such as robotic arms and conveyor belts. Its maintenance-free characteristics can reduce downtime and improve operational reliability.

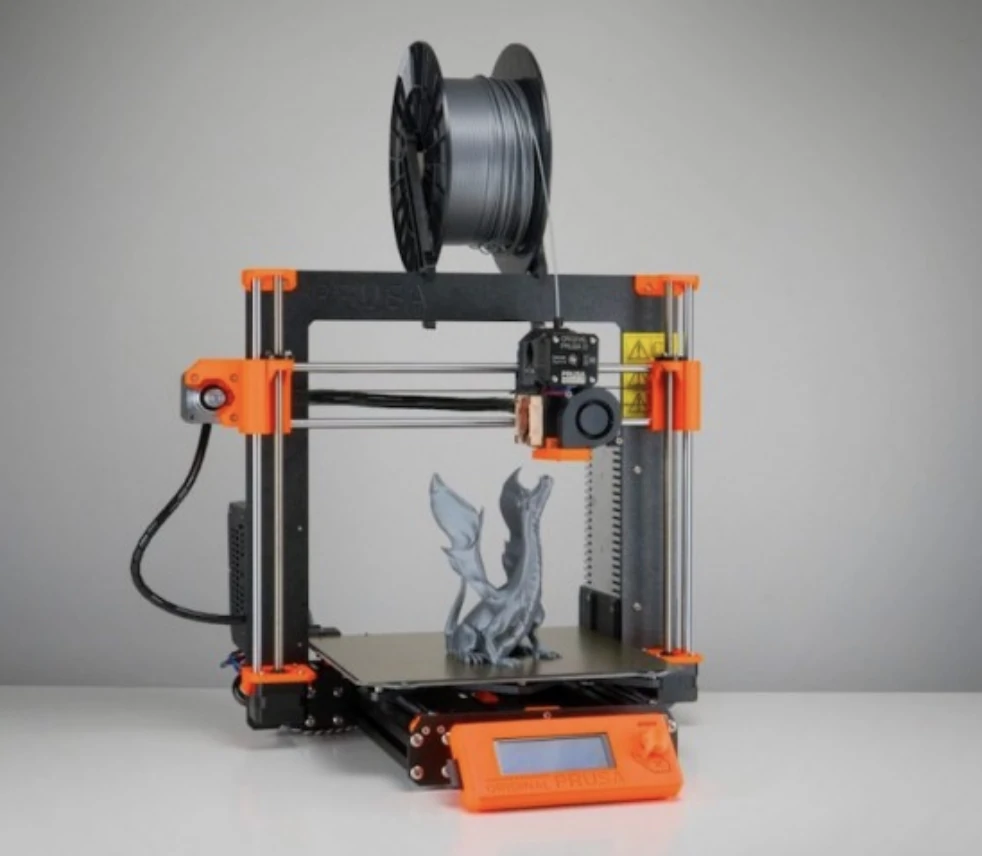

Additive manufacturing equipment

In the motion modules of 3D printers (such as printing platforms and drive shafts), low friction coefficients help improve positioning accuracy.

Agricultural and forestry machinery

Resistant to muddy water erosion and impact loads, it is often used in joints of outdoor equipment such as seeders and harvesters.

Medical equipment

Meet the requirements of sterile environments and are used for high-precision moving parts such as imaging equipment and surgical robots.

Food processing industry

Meet food safety standards and can work for a long time in places where cleaning agents are frequently contacted.

FAQ

Q1: Can metal bearings be completely replaced?

Plastic Linear plain Bearings are more suitable for medium and low speed, light and medium load scenarios, while metal rolling bearings are still required for high load or high speed conditions.

Q2: Is it necessary to add lubricant?

In most cases, no lubrication is required, but auxiliary lubrication measures can be considered under extreme temperature or chemical exposure conditions.

Q3: What are the key factors for selection?

The load, movement speed, temperature range and medium corrosiveness need to be comprehensively evaluated. For example, PTFE is resistant to high temperature, and POM is suitable for high speed.

Q4: How to estimate the service life?

It is directly related to the working conditions. Under reasonable use, the service life can reach thousands to tens of thousands of hours. Overload or high speed will accelerate wear.

Q5: What are the core advantages?

Self-lubrication, corrosion resistance, vibration reduction and noise reduction, lightweight and low-cost maintenance are its main competitive advantages.

Conclusion

Plastic Sliding Linear bearings have outstanding performance in reducing friction, reducing noise and adapting to complex environments due to their unique material properties. They have become important components in the automation, medical and food industries. The model selection should be based on the specific working conditions and the wear should be checked regularly to optimize the service life. If further technical support is required, you can contact the professional team at any time to get the solution.