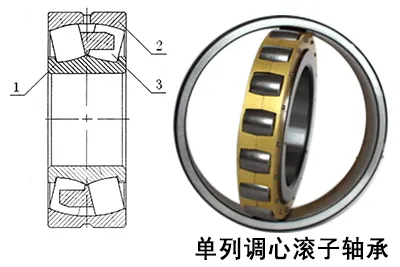

Single Row Spherical roller bearings

Single row spherical roller bearings have the following performance and characteristics:

Automatic self-aligning ability: the outer ring is spherical design, which can automatically adjust the deviation of the shaft or bearing seat and reduce the installation accuracy requirements.

- High load carrying capacity,

- Strong durability,

- Excellent vibration resistance,

- Strong adaptability

These features make it an ideal choice for heavy load and high vibration environments.

Overview of Single Row Spherical roller bearings

Single-row spherical roller bearings (SRR) are Spherical roller bearing that can withstand both radial and axial loads. The inner and outer raceways are spherical in design and have an automatic self-aligning function, which can effectively cope with shaft offset or installation deviation, ensuring stable performance, making them an ideal choice for a variety of industrial applications.

Core features

Automatic self-aligning function: The spherical raceway design can compensate for the angular deviation between the shaft and the bearing seat, reducing the risk of failure caused by installation errors or shaft deformation.

- High load capacity: It can withstand large radial loads and support medium axial loads in both directions.

- Excellent durability: The structure is strong and the service life is long, suitable for heavy loads and high-intensity conditions.

Application areas of Single Row Spherical roller bearings

Single-row spherical roller bearings are widely used in the following scenarios:

- Motors: Suitable for high-power industrial motors, especially large equipment that needs to withstand both radial and axial loads.

- Metallurgical equipment: Used in machinery such as mills, crushers and conveyors, and can cope with heavy loads and shock loads.

- Mining machinery: Effectively handle high radial loads and vibrations in equipment such as crushers, screens and conveyors.

- Wind power generation: used in wind turbine generators to support the high loads generated by the blades.

- Construction equipment: suitable for heavy machinery such as cranes and excavators, which can withstand high radial and axial loads.

- Transportation equipment: used in railway and automobile wheels, axles and other components to meet high load and durability requirements.

Product Models and Specifications Table

Here is a table of common single-row spherical roller bearings and their specifications:

Parameters Explanation:

- Inner Diameter (d): The inner diameter of the bearing, typically matching the shaft size, given in millimeters (mm).

- Outer Diameter (D): The outer diameter of the bearing, given in millimeters (mm).

- Width (B): The width of the bearing, given in millimeters (mm).

- Dynamic Load Rating (C): The maximum dynamic load the bearing can handle, given in kilonewtons (kN).

- Static Load Rating (C₀): The maximum static load the bearing can handle, given in kilonewtons (kN).

- Max Speed (r/min): The maximum rotational speed of the bearing, given in revolutions per minute (rpm).

- Weight (kg): The weight of the bearing, in kilograms (kg).

Single Row Spherical Roller Bearings are highly adaptable and durable components, known for their impressive load-bearing capabilities and superior self-aligning properties. Engineered to manage both radial and axial forces, they are particularly suited for situations involving misalignment and significant loads.

These bearings find extensive use in sectors like electric motors, metallurgical processes, mining operations, wind energy systems, construction machinery, and rail transport, where their capacity to withstand substantial radial forces and sudden impacts is essential. Their robust construction and minimal maintenance needs contribute to extended service life and decreased downtime for replacements or repairs.

By choosing the right model, these bearings can perform reliably in various challenging conditions, guaranteeing top-tier performance, efficiency, and dependability for the equipment they are part of.