Bearings are widely used in the food and packaging industry, especially in food processing, packaging and transportation. Food and packaging equipment needs to run efficiently and smoothly while meeting strict hygiene standards, so the selection and application of bearings need to be particularly cautious. The following are the main application scenarios of bearings in this field:

Food processing equipment

During the food processing process, bearings are widely used in equipment such as cutters, mixers, juicers, and grinders. These equipment need to run efficiently and stably while avoiding pollution, so bearings need to be resistant to high temperatures, corrosion and pollution.

- Stirring and mixing equipment: Bearings support rotating parts to ensure smooth operation of the equipment, and must be waterproof and anti-fouling.

- Cutting and grinding equipment: Bearings help maintain the stability of the tool and reduce friction during high-speed operation.

- Temperature control equipment: In high-temperature environments (such as baking and cooking), bearings need to be resistant to high temperatures to ensure stable operation of the equipment.

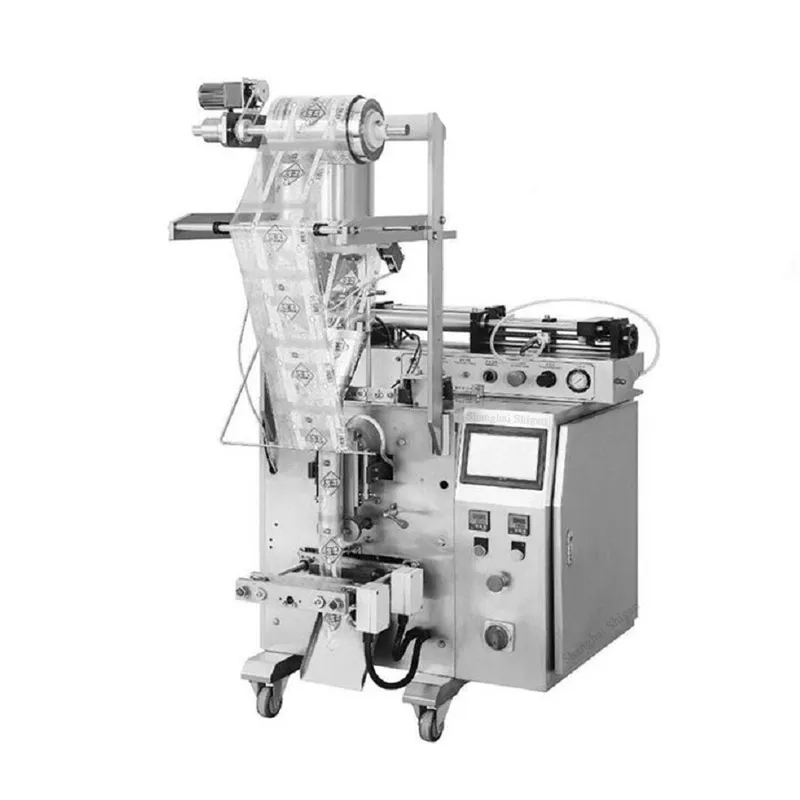

Packaging equipment

Automated production lines in the packaging industry rely on a variety of equipment, such as packaging machines, filling machines, labeling machines, etc., in which bearings play a key role.

- Automatic packaging machines: Bearings ensure smooth operation of conveyor belts and packaging equipment for precise control.

- Filling and labeling machines: Bearings support liquid filling systems and label placement devices to ensure accurate operation.

- Packaging equipment: Bearings reduce friction in mechanical movement, improving equipment life and production efficiency.

Conveying equipment

Conveying equipment is crucial in the food and packaging industries. Bearings are used to support conveyor belts, rollers and chain drive systems to ensure smooth flow of materials.

- Conveyor belts: Bearings reduce resistance in material transportation and ensure smooth operation of conveyor belts.

- Roller systems: Bearings reduce friction and prevent premature equipment damage.

- Chain conveyors: Bearings support chain drive wheels and tensioning systems to ensure stable operation.

Cooling and freezing equipment

In food cooling and freezing equipment, bearings support components such as motors and fans to ensure stable operation of equipment in low temperature environments.

- Freezer compression systems: Bearings reduce friction and ensure stable operation of compressors.

- Cooling fans and heat dissipation systems: Bearings help fans rotate smoothly, ensure cooling effects and reduce noise.

Cleaning equipment

Cleaning equipment in the food industry relies on bearings to support rotating parts and ensure long-term stable operation of the equipment.

- Bottle and can washers: Bearings ensure smooth operation of rotating parts and improve cleaning results.

- Spray cleaning system: Bearings support the rotation of the nozzle to ensure uniform spraying of detergent.

Aseptic production equipment

During the aseptic production process, bearings need to have anti-contamination and anti-bacterial properties. Common materials include stainless steel and ceramics.

- Stainless steel bearings: Corrosion-resistant, suitable for humid or high-salt environments.

- Sealed bearings: Prevent bacteria and contaminants from entering to ensure food quality.

Food conveying and sorting

Automated sorting systems rely on bearings to ensure accurate sorting and conveying of products.

- Automatic sorting machines: Bearings support robotic arms and conveyor belts to ensure sorting accuracy.

- High-speed conveying systems: Bearings ensure fast and smooth material delivery to avoid jamming and damage.

Sealing and protective equipment

In equipment such as sealing machines and filling machines, bearings help moving parts operate stably, reduce friction, and improve efficiency.

Резюме

Bearings are very important in the food and packaging industry. They ensure the efficiency and stability of food production, processing, packaging and transportation. To meet the special requirements of the food industry, bearings need to be resistant to corrosion, pollution and high temperature, so stainless steel, ceramic and other materials are widely used. By reducing friction, improving efficiency and extending equipment life, bearings play a key role in ensuring food quality, safety and production efficiency.