Angular Contact Deep Groove Ball Bearings

Angular contact deep groove ball bearings combine the characteristics of deep groove ball bearings and angular contact ball bearings.

- High load-bearing capacity

- High rotational speed and high precision

- Low friction and low noise.

- Long service life

- High rigidity and smooth running

Angular contact deep groove ball bearings are one of the many types of Deep Groove Ball Bearings, where the contact angle between the inner and outer rings is increased (usually 15°, 30° or 40°), allowing them to withstand both radial and axial loads. This design is to adapt to the high precision and high reliability of the application range, can withstand higher speeds of rotation and higher axial loads.

Compared to normal deep groove ball bearings, Angular Contact SKF Deep Groove Ball Bearings are optimised for the intended application and can withstand a combination of both radial and axial loads. The contact angle is the main reference for how much axial load the bearing can withstand. The greater the contact angle, the greater the axial load capacity.

Main Models and Specifications

Below is a table of common angular contact deep groove ball bearing models and their basic specifications:

Applications

Angular contact deep groove ball bearings are used in a wide range of industries and applications:

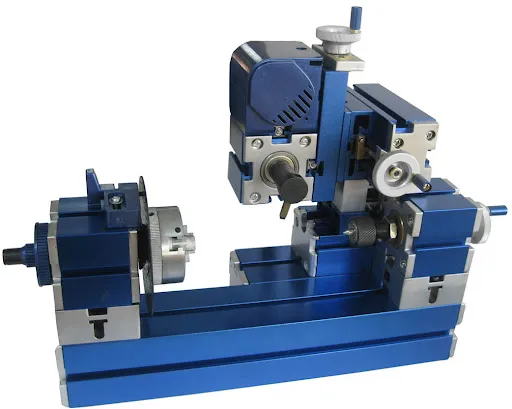

1. Machine Tools:

Angular contact bearings are commonly used in the spindle systems of machine tools to ensure high precision and stable operation at high speeds.

2. Power Tools:

High-speed power tools (such as drills, grinders, and sanders) require bearings that can handle both radial and axial loads. Angular contact deep groove ball bearings provide the necessary performance for these applications.

3. Automotive:

In automotive systems, such as transmissions, steering systems, and wheel hubs, angular contact bearings are used to handle combined radial and axial loads, ensuring smooth and reliable operation.

4. Aerospace and Aviation:

Angular contact bearings are widely used in aerospace components, such as aircraft engines and turbines, where high-speed and high-load capacity are critical for performance.

5. High-Speed Motors and Precision Equipment:

In high-speed motors and precision equipment, these bearings offer excellent load-handling capability and low friction, ensuring high efficiency and accuracy.

6. Wind Turbines:

Angular contact deep groove ball bearings are used in wind turbine systems to manage radial and axial loads, helping to ensure efficient and reliable operation.

Features

1. High Load Capacity:

Angular contact deep groove ball bearings can simultaneously support substantial radial and axial loads, particularly making them suitable for applications with combined loading conditions.

2. High-Speed Performance:

These bearings are designed to operate at high speeds while maintaining stable performance, making them ideal for high-speed machinery.

3. Precision and Stability:

Angular contact bearings provide high operational precision with low vibration and noise, making them suitable for precision machines and instruments.

4. Ability to Handle Single or Double Axial Loads:

Depending on the contact angle, angular contact deep groove ball bearings can be designed to handle either single-direction or bidirectional axial loads, offering flexibility in various applications.

5. High Temperature and Wear Resistance:

The materials and lubricants used in angular contact bearings ensure good resistance to high temperatures and wear, providing a long service life under demanding conditions.

6. Good Sealing Performance:

Many angular contact bearings come with seals or shields, which protect the bearing from contamination and extend its lifespan.

FAQ:

1. What is the basic structure and working principle of angular contact deep groove ball bearings?

Angular contact deep groove ball bearing consists of inner ring, outer ring, rolling body (steel ball) and cage. Its working principle is, when the inner ring or outer ring is subjected to rotating torque, the rolling body in the inner and outer ring raceway rolling between, so as to achieve the transmission of force and the conversion of movement. Because the rolling body and the raceway for the point contact or line contact, so has a high bearing capacity and running accuracy.

2. What are the main failure modes of angular contact deep groove ball bearings?

Angular contact deep groove ball bearing failure mode mainly includes wear failure, fatigue failure, fracture failure, corrosion failure and lubrication failure. Wear failure is due to the rolling body and raceway between the contact stress is too large caused by the surface material spalling; Fatigue failure for rolling body or raceway surface cracks, spalling or fracture; Fracture failure is a part of the bearing (such as the rolling body, inner ring, outer ring or cage) fracture; Corrosion failure is the surface of the bearing rust, corrosion pits or corrosion phenomenon; Lubrication failure is due to the improper selection of lubricant or Lubrication failure is due to improper selection of lubricants or poor lubrication caused by

3. What is the main difference between angular contact deep groove ball bearings and deep groove ball bearings?

Angular contact deep groove ball bearings and deep groove ball bearings in the outer ring, inner ring and steel ball layout has significant differences. Deep groove ball bearing outer ring groove design is deeper, with double shoulders on both sides, mainly to withstand radial load; while angular contact deep groove ball bearing outer ring groove curvature is larger, usually for the single-shoulder design, can withstand radial load and axial load at the same time. In addition, the larger the contact angle of angular contact deep groove ball bearings, the stronger its axial load capacity, suitable for the need to withstand a larger axial load occasions

4. What are the application scenarios of angular contact deep groove ball bearings?

Angular contact deep groove ball bearings are widely used in a variety of applications that require high precision and high load capacity. Single-row angular contact deep groove ball bearings are suitable for machine tool spindles, high-frequency motors, combustion turbines and so on; double-row angular contact deep groove ball bearings are suitable for oil pumps, Roots blowers, air compressors and so on. Because it can withstand radial load and axial load at the same time, especially in the need to withstand a large axial load occasions outstanding performance, so it is widely used in a variety of mechanical equipment.

5. How to choose the right angular contact deep groove ball bearings?

The following factors need to be considered when choosing the right angular contact deep groove ball bearings:

Load capacity: according to the load requirements of the application scene to choose the appropriate contact angle and load capacity.

Speed requirement: the smaller the contact angle is, the more favourable it is to high speed rotation, choose the suitable contact angle to meet the speed requirement.

Installation and Adjustment: Consider the convenience of installation and adjustment, and select the bearings with reasonable design to adapt to different working conditions.

Application scenarios: according to the specific application scenarios to choose single-row or double-row bearings, as well as the need to use in pairs to improve rigidity and precision.

Factory Warehouse: