Basic Self-aligning Ball Bearings

The basic self-aligning ball bearing

Main application scenarios:

Transmission systems with shaft bending or installation centering errors (such as long shafts, multi-support shaft systems)

Equipment that is prone to vibration in the working environment (such as motors, pumps, fans)

Heavy machinery that needs to adapt to base deformation (such as agricultural machinery, mining equipment)

Industrial transmission occasions with medium speed and medium load

Core advantages:

Automatic self-aligning ability: effectively absorb installation errors and reduce edge stress

Easy maintenance: standardized design, easy to install and replace

Economical and practical: lower cost than other self-aligning bearings (such as self-aligning roller bearings)

Adapt to multiple working conditions: can withstand radial loads and cope with certain axial forces

Low friction design: optimized raceway geometry, low running resistance

Basic Self-aligning Ball Bearing Overview

Basic Self-aligning Ball Bearings are rolling bearings with automatic correction function, which can effectively adapt to the installation deviation between the shaft and the bearing seat or the deformation of the shaft body. Its uniqueness lies in the spherical structure of the outer ring raceway, which allows the inner ring, rolling element and cage to be freely adjusted within a certain angle, thereby avoiding bearing failure caused by poor alignment.

The design advantage of this bearing is that even if there is a shaft offset or assembly error, the contact point between the raceway and the rolling element can still maintain the best alignment to ensure stable operation.

Standard Specifications

The following table lists typical self-aligning ball bearing models and their key performance indicators:

Parameter Description

Inner diameter: key dimension that matches the shaft diameter.

Outer diameter: diameter of the outer ring of the bearing, which determines the installation space.

Width: axial dimension of the bearing.

Dynamic/static load: refers to the load-bearing capacity of the bearing in rotating and stationary states respectively.

Limiting speed: the maximum allowable operating speed, which is affected by lubrication and heat dissipation conditions.

Unit weight: the mass of a single bearing, which affects the total weight of the equipment.

Common brands

SKF basic self-aligning ball bearings

FAG basic self-aligning ball bearings

NSK basic self-aligning ball bearings

INA basic self-aligning ball bearings

KOYO basic self-aligning ball bearings

TIMKEN basic self-aligning ball bearings

NTN basic self-aligning ball bearings

Typical application scenarios

Basic self-aligning ball bearings are widely used in the following fields due to their adaptive characteristics:

Industrial power equipment: such as motors, water pumps, etc., which can relieve additional stress caused by assembly errors or shaft deflection.

Agricultural machinery: Equipment such as tractors and combine harvesters need to rely on their anti-sway ability under complex working conditions.

Renewable energy: Wind turbine main shafts often use this type of bearing to cope with tower deformation or foundation settlement.

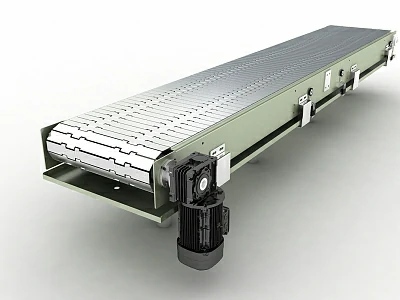

Material conveying system: Conveyor belt rollers, drive shafts and other components that require long-term stable operation.

Transportation: Suitable for vehicle suspension or transmission components to adapt to dynamic load changes.

FAQ

Q1: What is the working principle of the basic self-aligning ball bearing?

A1: The outer ring raceway is a spherical design, allowing the inner ring assembly to maintain effective contact between the rolling element and the raceway during deflection, thereby offsetting installation deviations.

Q2: What working conditions are suitable for this type of bearing?

A2: Suitable for equipment with shaft bending, uneven base or dynamic alignment requirements, such as heavy machinery, long shaft transmission systems, etc.

Q3: What is the load bearing capacity of the bearing?

A3: Mainly radial load, can withstand moderate axial load; if higher axial load capacity is required, it is recommended to choose tapered roller bearings or thrust bearings.

Q4: What should be paid attention to in daily maintenance?

A4: Regularly add or replace lubricants to prevent contaminants from entering; stop and check when abnormal vibration or temperature rise occurs.

Q5: What factors affect the speed limit of the bearing?

A5: The larger the size, the lower the limit speed; the speed capacity of sealed bearings is usually lower than that of open designs.

Conclusion

The basic self-aligning ball bearing significantly improves the reliability of the equipment under misalignment conditions due to its unique adaptive performance. We Chinese ball bearing suppliers assure you, correct selection and regular maintenance can extend its service life and is suitable for industrial scenarios with high dynamic loads or limited installation accuracy.