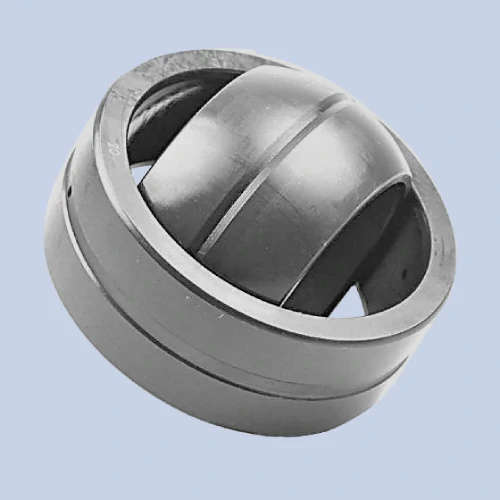

Radial spherical plain bearings

Core advantages of radial spherical plain bearings

✔ Self-aligning – adapts to shaft deflection, reduces edge stress and prolongs life.

✔ Impact resistance – sliding friction structure is more resistant to vibration and impact loads than rolling bearings.

✔ Anti-pollution – sealed design (such as PTFE bushing) is suitable for harsh environments such as dust and moisture.

✔ Maintenance-free (optional) – self-lubricating models do not require frequent greasing, reducing maintenance costs.

✔ High load – steel back + copper alloy/polymer bushing design, suitable for low-speed and heavy-load conditions.

Typical applications

🔧 Construction machinery – excavator arm hinge point, crane swivel support (compensation for structural deformation).

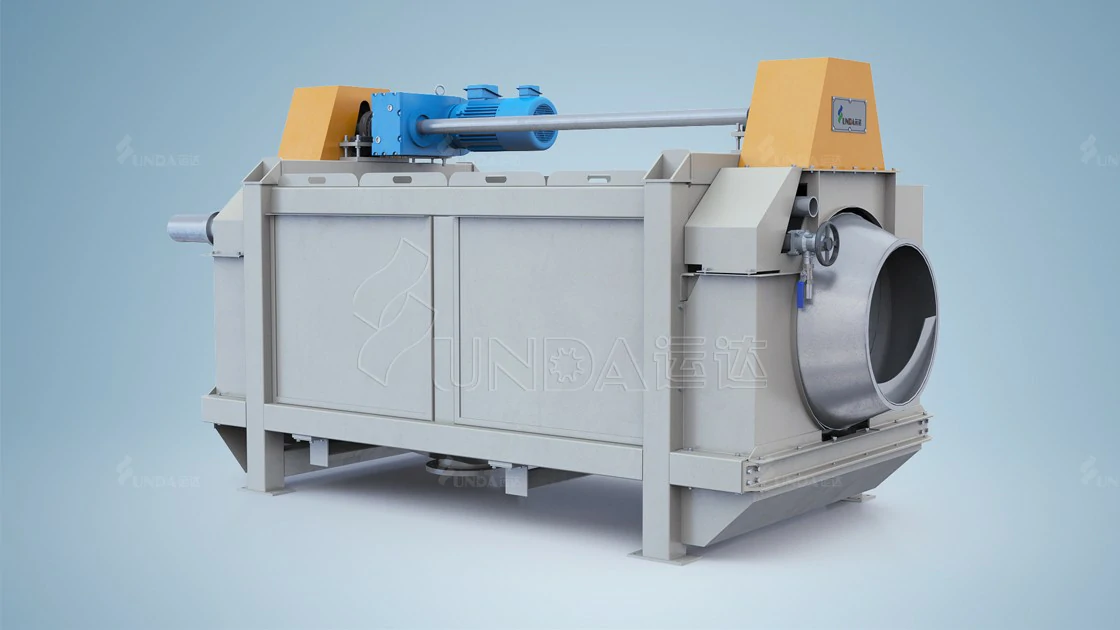

🌾 Agricultural machinery – tractor drive shaft, harvester connecting rod (resistant to mud, water, sand and dust).

🏭 Industrial equipment – paper machine drum, conveyor belt roller (corrosion-resistant, rust-proof coating).

⚡ Heavy industry – metallurgical mills, mining crushers (high impact + slow speed heavy load).

1. Overview of Radial Spherical Plain Bearings

Definition:

A radial spherical plain bearings (Self-aligning Radial Plain Bearing) are the type of sliding bearing that allows a certain angular error between the shaft and the bearing seat (usually 2-3°). It can achieve self-alignment through its spherical structure and compensate for the effects of installation errors or shaft bending.

Structural features:

Inner ring: spherical outer diameter, tightly matched with the bearing seat.

Outer ring: spherical inner diameter, matched with the shaft neck.

Sliding material: usually steel back composite material and copper/PTFE material or coating are used to reduce the friction coefficient.

2. Common models and size parameter table

1. Standard model examples (taking GE series as an example)

2. Comparison with other series

SA series: suitable for heavy-duty applications, with a larger outer diameter (for example, SA40, inner diameter 40mm, outer diameter 80mm).

GEC series: with flange design, suitable for occasions requiring axial positioning.

Common brands:

We have these brand of Spherical Sliding Bearings now:-

SKF radial spherical sliding bearing

FAG radial spherical sliding bearing

NSK radial spherical sliding bearing

KOYO radial spherical sliding bearing

TIMKEN radial spherical sliding bearing

INA radial spherical sliding bearing

NTN radial spherical sliding bearing

3. Application analysis

1. Typical application scenarios

Engineering machinery: such as the hinge point of the excavator arm, compensating for the deformation of the structure.

Agricultural equipment: For example, the drive shaft of the harvester adopts a dustproof seal design.

Industrial transmission: such as the roller of the paper machine, using corrosion-resistant coating materials.

2. Selection points

Load: When the dynamic load is greater than the static load, copper-based materials should be preferred.

Speed: PTFE bushings are suitable for high-speed applications (<500rpm), while copper alloys are more suitable for low-speed and high-load working conditions.

Environment: In a humid environment, it is recommended to choose a stainless steel housing and sealing design (such as GE...ES-2RS).

4. FAQ

Q1: How to determine whether the bearing needs lubrication?

Non-self-lubricating models (such as GE30C) require regular addition of lithium-based grease; while self-lubricating models (models with the "ES" suffix) do not require maintenance.

Q2: What is the maximum allowable misalignment angle during installation?

Generally 2-3°. If this range is exceeded, it may cause edge stress concentration, thereby shortening the bearing life.

Q3: What may be the cause of abnormal noise from the bearing?

Possible reasons include:

① Insufficient lubrication;

② Dust ingress;

③ Wear of spherical coating (needs to be replaced).

Q4: What is the advantage of radial spherical sliding bearings compared to spherical roller bearings?

It has strong impact resistance and anti-pollution ability, but is suitable for lower speeds.

5. Maintenance recommendations

Regular inspection: Check the wear every 6 months, especially for bearings in heavy-duty applications.

Lubrication cycle: Non-self-lubricating models need to be re-greased after every 500 hours of work.

Replacement criteria: When the radial clearance exceeds 0.15mm or plating peeling occurs, the bearing needs to be replaced.